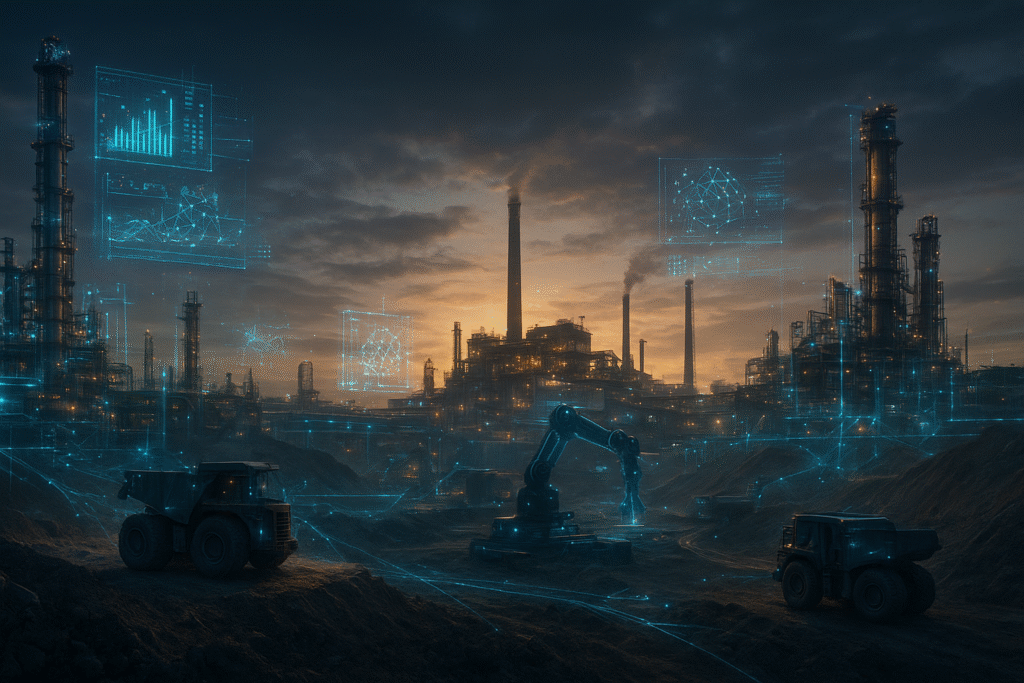

A Seismic Shift: From Manual to Autonomous

The impact is staggering. McKinsey predicts that by 2030, autonomous systems will cut operational costs by 20–30% in these sectors. But how is this technological convergence making an entire industry ecosystem intelligent? The answer lies in its three core pillars.

The Three Pillars of Autonomous Operations

1. The Nervous System: IoT Sensor Networks

Before any system can become intelligent, it needs to gather data. This is the role of the Internet of Things (IoT). Thousands of interconnected sensors are embedded in equipment, pipelines, and machinery. They act as the industry’s nervous system, monitoring everything from temperature and pressure to vibration and flow rates in real-time. This flood of data provides a level of situational awareness that was previously unimaginable.

Case in Point: One major mining company deployed an IoT network to monitor its haulage equipment. By collecting real-time data on engine health and tire pressure, they were able to predict maintenance needs, which reduced costly downtime by 40%.

2. The Brain: AI-Driven Decision-Making

IoT sensors collect the data, but AI is what makes sense of it. Machine learning algorithms analyze these massive datasets to identify patterns, predict anomalies, and make autonomous decisions.

Real-World Example: Shell uses AI-powered drills that analyze geological data in real time to optimize extraction paths. This intelligent approach has led to 15% faster drilling times and a 10% reduction in waste, proving that smarter decisions lead to better outcomes.

3. The Digital Twin: A Risk-Free Sandbox

A digital twin is a virtual replica of a physical asset, continuously updated with real-time data from its IoT sensors. This creates a living, breathing simulation of the physical world. It’s the ultimate risk-free testing environment where operators can model and optimize everything from a single piece of equipment to an entire refinery without impacting real-world operations.

Real-World Applications Transforming Industries

Beyond theory, autonomous solutions are delivering massive results across the board.

- Oil & Gas: Companies like BP are using AI-powered drones to inspect thousands of miles of pipelines. The AI analyzes high-resolution imagery to detect corrosion or hairline cracks with incredible accuracy, leading to a 50% reduction in leaks.

- Mining: The future is here with autonomous haulage systems (AHS). Companies like Rio Tinto have deployed fleets of self-driving trucks in their mines. These systems run 24/7 without a driver and optimize fuel consumption, resulting in a 30% reduction in fuel costs.

- Manufacturing: In the world of manufacturing, robotics and AI are working together to enforce strict quality control. Siemens’ facilities use AI to analyze images of newly manufactured parts, catching even microscopic defects with 99.8% accuracy, ensuring flawless products reach the market.

Overcoming the Hurdles: Challenges and Solutions

The journey to autonomy isn’t without its challenges.

- High Upfront Costs: Implementing these complex systems can be a significant initial investment.

- The Solution: Companies are adopting modular AI tools from providers like AWS Industrial IoT. This allows for a phased approach, where you can start small with a single use case and scale your investment over time.

- Workforce Resistance: The fear that automation will replace human jobs is a common concern.

- The Solution: The focus is shifting from replacement to empowerment. Companies are investing in upskilling programs and Digital Twin Academies to train their existing workforce on how to manage and interact with these new systems. The human role evolves from manual labor to strategic oversight and data-driven decision-making.

The Future: What’s Next for Autonomous Operations?

Looking ahead, the pace of innovation is only accelerating. The integration of 5G and Edge AI will enable real-time processing of data directly at the source, powering instantaneous decisions in remote locations.

The next frontier is self-healing systems—AI that not only predicts equipment faults but also automatically initiates repairs or reroutes operations to compensate. This will create truly resilient industrial ecosystems that can manage themselves with unprecedented efficiency and reliability.